B-TEC’s strength

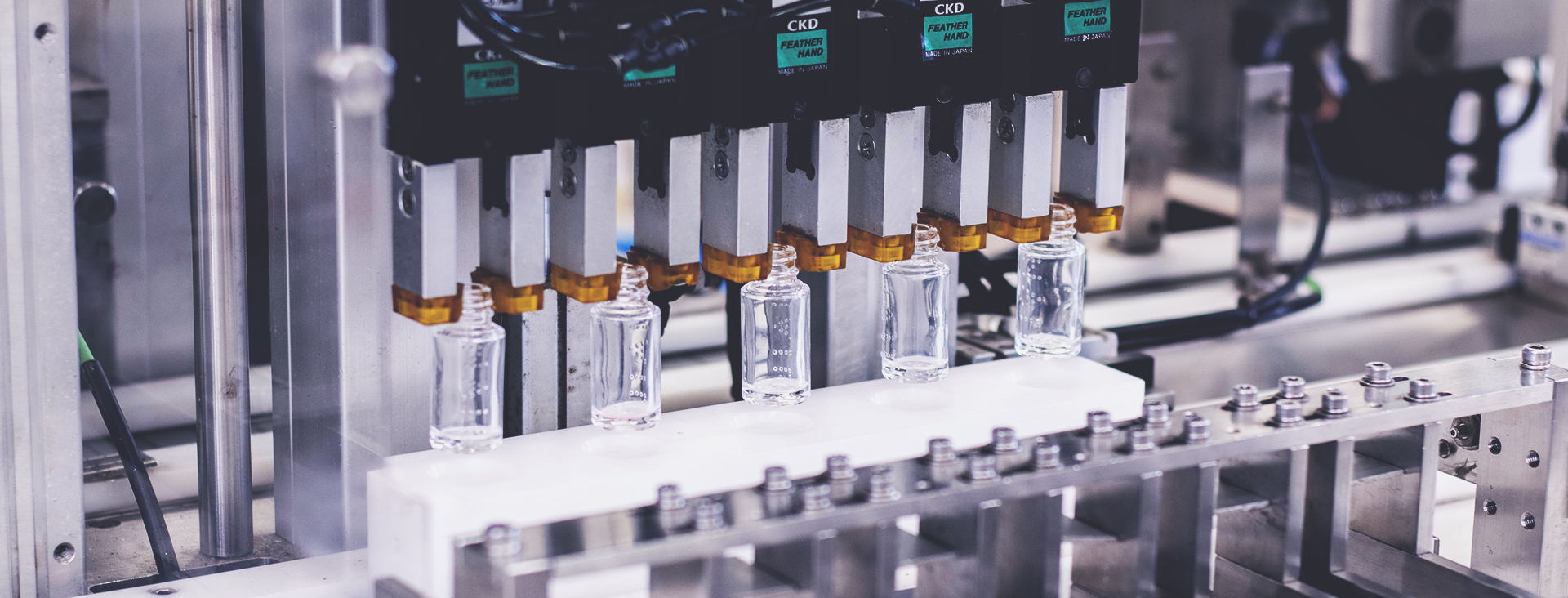

Air barrier

In order to protect the quality of our products, we manage the air conditioning [positive pressure] in each filling room in accordance with GMP “Good Manufacturing Practice.”

Air has the characteristic of flowing from high pressure to low pressure, so by continuing to supply clean air that has passed through a special filter into the room, the air containing dust and viruses that originally existed in the room can be removed. The mechanism is such that it is pushed out into clean air.

An invisible barrier is created using air pressure, creating an environment that prevents outside air from penetrating.

Dealing with

small lots

By ordering in small lots, there are advantages such as reducing costs and not having to keep inventory.

Our company makes management efforts to eliminate waste in the manufacturing process, and we can accommodate minimum lots of 1000 pieces. Please feel free to contact us.

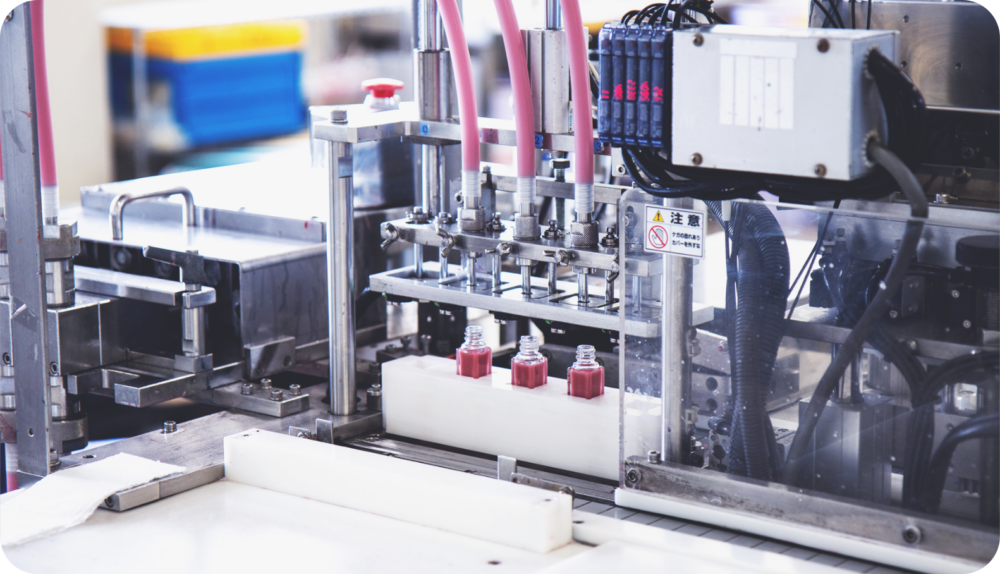

Explosion-proof equipment

We have a hazardous materials building for nail polish filling.

This is an explosion-proof building and also manufactures colognes, perfumes, nail polish remover, etc.

Annual production of 100 million packages

Our company has nine filling machines for sample pouches (four-sided seals), and the total annual production exceeds 100 million bags.

We keep in mind a streamlined schedule and are able to accommodate even relatively short delivery times.

In addition, we have engineers with many achievements and experience, so we are confident in our quality.